Overview of Purchasing in Oracle Apps

Create requisition to procure goods and service with supplier information, delivery instructions, multiple accounting distributions, and notes to buyers, approvers, and receivers. A request for quotation (RFQ) is sent to a supplier to request pricing and other information for an item. A quotation is the supplier’s response to that RFQ. Identify requisitions that require supplier quotations and automatically create a RFQ Or create manually and send it thru’ Fax or iSupplier portal. Record supplier quotations from a catalog, telephone conversation, or response from your RFQ. You can also receive quotations electronically and import as Quotations (catalog). Review, analyze, evaluate and approve supplier quotations. Create standard purchase order, BPA and blanket releases. Inform your suppliers of your shipment schedule requirements. Record supplier acceptances of your purchase order’s terms and conditions. Provide a quantity and price for each item you are ordering. Alternatively, you should also be able to create your purchase order simply by providing an amount if you are ordering a service that you cannot break down by price and quantity. Enter goods and service receipt information against the PO using routing controls viz: Direct delivery, standard receipt or standard receipt with inspection. Transfer and deliver goods using the Receiving Transactions window. If you want to perform an inspection transaction, you can open the Inspections window to specify accepted and rejected quantities.

This cycle involves following steps from creating a requisition to transfer the details to GL.

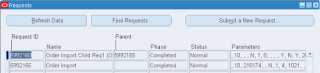

1. Create Requisition

Approve requisition

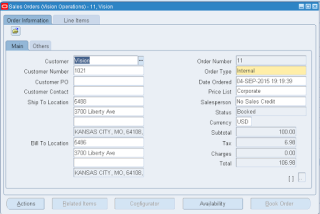

2. Create Purchase Order

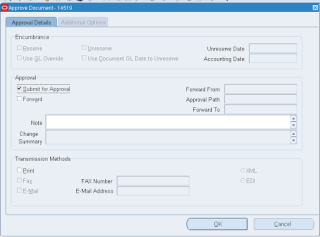

Approve Purchase Order

3. Create Receipt after receiving the goods

4. Create an Invoice in AP

5. Pay the invoice

6. Transfer, Import and Post Journal to GL

Basic Components of Procurement

Requisition

Requisition is nothing but a formal request to buy something (like Inventory material, office supplies etc) needed for the enterprise. Only an employee can create one.

With on-line requisitions, you can centralize your purchasing department, source your requisitions with the best suppliers, and ensure that you obtain the appropriate management approval before creating purchase orders from requisitions.

Purchasing provides you with the features you need to satisfy the following basic requisition needs. You should be able to:

· Create, edit, and review requisition information on-line. You should also be able to enter suggested supplier information, delivery instructions, multiple accounting distributions, and notes to buyers, approvers, and receivers.

· Review the current status and action history of your requisitions. You should always know who approves requisitions and whether they are in the approval, purchasing, receiving, or delivery stage.

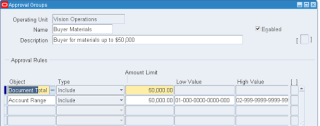

· Route requisitions according to your approval structure. You should also be able to set authorization limits by amount, charge account, item category, and location.

· Review and approve requisitions that need your approval. You should also be able to see the full requisition detail and review the action history before you approve a requisition.

· Print requisitions (with status Approved, Cancelled, Rejected, In Process, Pre-Approved, and Returned) for off-line review and approval. You should always be able to track the status of requisitions through the approval process.

· Import requisitions from other systems such as material or distributions requirement planning applications

· Perform on-line funds checking before creating requisitions. You should always know how your planned expenses compare to your budget.

· Automatically source requisitions from outstanding blanket purchase agreements or quotations you have received from suppliers

· Create requisitions quickly and easily for commonly purchased items

· Provide attachments as notes on requisition headers and lines

· Assign requisition lines to buyers and review buyer assignments for requisition lines

· Forward all requisitions awaiting approval from one approver to an alternate approver. Within your security and approval constraints, you should be able to reroute requisitions from one approver to another whenever you want.

· Record suggested foreign currency information for each requisition line

Requisition Types:

1. Purchasing Requisition: Purchase requisitions are used for requesting material from suppliers.

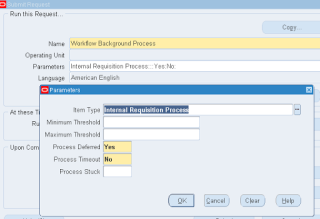

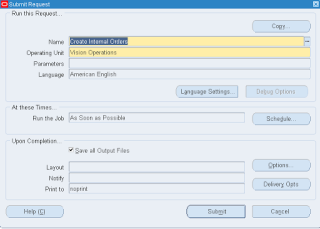

2. Internal Requisition: Internal requisitions provide the mechanism for requesting and transferring material from one inventory to other inventory

RFQ

A request for quotation (RFQ) is sent to a supplier to request pricing and other information for an item. A quotation is the supplier’s response to that RFQ. You send an RFQ to a supplier by fax, making a phone call, or using Oracle iSupplier Portal. A supplier can send a quotation, whether or not in response to an RFQ, is through the Purchasing Documents Open Interface.If you don’t receive quotations electronically from your supplier, you can create the quotation manually using the Quotations window, or copy the quotation from an RFQ.

Using Quotation for Purchase Order

When you create a purchase order (manually or from requisitions), you can use the Supplier Item Catalog window to retrieve quotation information. (The Supplier Item Catalog window can include quotations sent to you by your supplier through the Purchasing Documents Open Interface.) Purchasing provides all your approved quotation shipment information for a specific item or manufacturing category. You can copy this quotation shipment to an existing blanket purchase agreement or standard purchase order when you add this item or purchasing category to a purchase order line. You can sort this quotation information according to your needs, using criteria such as price or quantity. You can easily evaluate the source that is best for an item.

After you select the quotation shipment you want to use, Purchasing copies the item unit price, quantity, unit of measure, supplier product number, inspection required status, receipt required status, quotation number, quotation type, and supplier quotation number on your purchase order. Purchasing also copies the quotation item description on your purchase order if you define your items to do so. Purchasing automatically warns you when the terms and conditions of the quotation are different from the terms and conditions of your purchase order. The original purchase order terms and conditions remain unchanged.

Types of Quotations

There are three types of quotations and RFQs that come with Purchasing by default:

Bid: Used for a specific, fixed quantity, location, and date. For example, a Bid would be used for a large or expensive piece of equipment that you’ve never ordered before, or for an item that incurs transportation or other special costs. You cannot specify price breaks for a Bid quotation or RFQ.

Standard: Used for items you’ll need only once or not very often, but not necessarily for a specific, fixed quantity, location, and date. For example, you could use a Catalog quotation or RFQ for office supplies, but use a Standard quotation or RFQ for a special type of pen you don’t order very often. A Standard quotation or RFQ also includes price breaks at different quantity levels.

Catalog: Used for high–volume items or items for which your supplier sends you information regularly. A Catalog quotation or RFQ also includes price breaks at different quantity levels.

For all three types, you can define effectivity dates at the header level.

For Catalog and Standard quotations, you can also specify effectivity dates for individual price breaks. (For a Bid, you cannot specify effectivity dates at the shipment level.) You can also define your own RFQ or quotation types using the

Document Types window.

Purchase Order

Purchasing provides the Purchase Orders window that you can use to enter Standard and planned purchase orders as well as Blanket and Contract purchase agreements. You must be defined as a buyer to use this window.

Purchasing provides you the features you need to satisfy the following purchasing needs. You should be able to:

· Review all of your purchases with your suppliers to negotiate better discounts

· Create purchase orders simply by entering a supplier and item details

· Create standard purchase orders and blanket releases from both on-line and paper requisitions

· Create accurate and detailed accounting information so that you charge purchases to the appropriate departments

· Check your funds availability while creating purchase orders.

· Review the status and history of your purchase orders at any time for all the information you need

· Print purchase orders flexibly by using a number of print options

· Inform your suppliers of your shipment schedule requirements

· Record supplier acceptances of your purchase orders. You always know whether your suppliers have received and accepted your purchase order terms and conditions

· Create your purchase orders by providing a quantity and price for each item you are ordering. Alternatively, you should also be able to create your purchase order simply by providing an amount if you are ordering a service that you cannot break down by price and quantity

Purchase Order Types

There are mainly 4 types of Purchase Orders

· Standard Purchase Order

· Blanket Purchase Agreements

· Contract Purchase Agreements

· Planned Purchase Orders

Standard Purchase Order

You generally create standard purchase orders for one-time purchase of various items. You create standard purchase orders when you know the details of the goods or services you require, estimated costs, quantities, delivery schedules, and accounting distributions.

Blanket Purchase Agreements (BPA)

You create blanket purchase agreements when you know the detail of the goods or services you plan to buy from a specific supplier in a period, but you do not yet know the detail of your delivery schedules. You can use blanket purchase agreements to specify negotiated prices for your items before actually purchasing them.

You can issue a Blanket release against a BPA to place the actual order (as long as the release is within the blanket agreement effectively dates).

Contract Purchase Agreements

You create contract purchase agreements with your suppliers to agree on specific terms and conditions without indicating the goods and services that you will be purchasing. You can later issue standard purchase orders referencing your contracts.

Planned Purchase Orders

A planned purchase order is a long-term agreement committing to buy items or services from a single source. You must specify tentative delivery schedules and all details for goods or services that you want to buy, including charge account, quantities, and estimated cost.

You can issue scheduled releases against a planned purchase order to place the actual orders. If you use encumbrance accounting, you can use the planned purchase order to reserve funds for long term agreements.